Got Aralac?

How milk substituted wool during WWII

One of the most enjoyable and rewarding aspects of museum work is the research process. A single object can lead you down a rabbit hole of interesting information. Sometimes, it’s the most ordinary-looking objects that reveal the most fascinating stories upon further investigation.

For example, this felt hat from the 1940s appears totally normal at first glance. The style is typical of the time period and its color does little to command attention. What’s striking about the hat is the fiber composition: a blend of 94% wool and 6% Aralac

Aralac is a fiber made from milk. The first commercially available milk fiber was invented by Italian chemist Antonio Ferrett in 1935 and sold under the name Lanital. A few years later, the American dairy industry was experimenting with ways to repurpose its waste products. In 1941, a division of the National Dairy Products Corporation (which later became Kraft Heinz) began to use skim milk, a by-product of butter production, to create their own version of milk fiber called Aralac.

The essential ingredient for Aralac is casein, the most commonly found protein in cow’s milk. To make Aralac, skim milk is first chemically treated to separate out its casein. The resulting solution is then placed in various water and solvent baths before being processed through a spinneret at high pressure. Finally, the fiber is ready to be spun into yarns and then knit or woven into fabric.

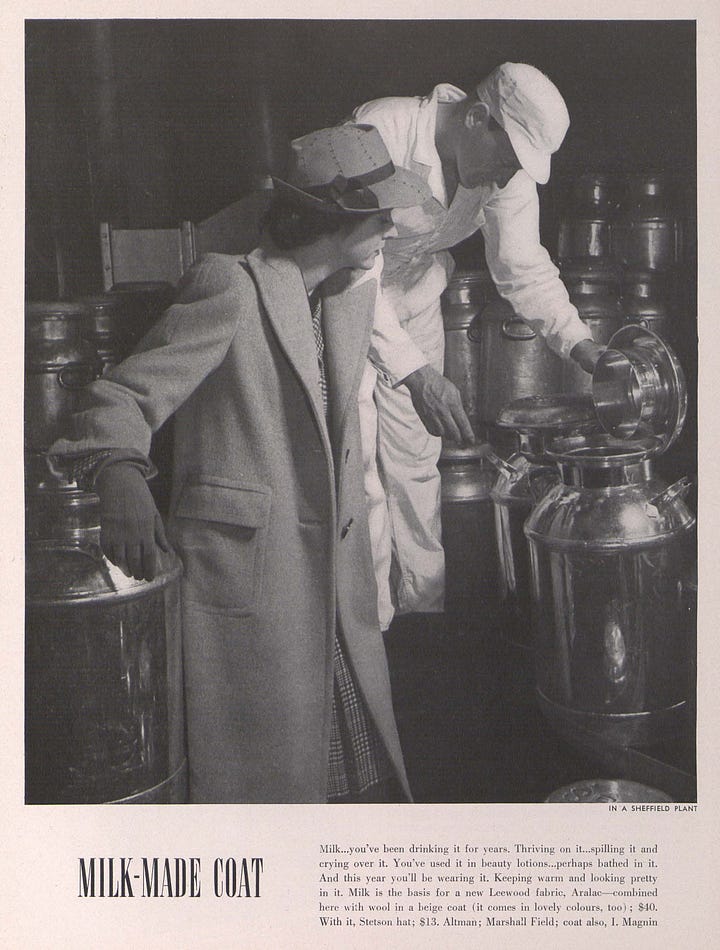

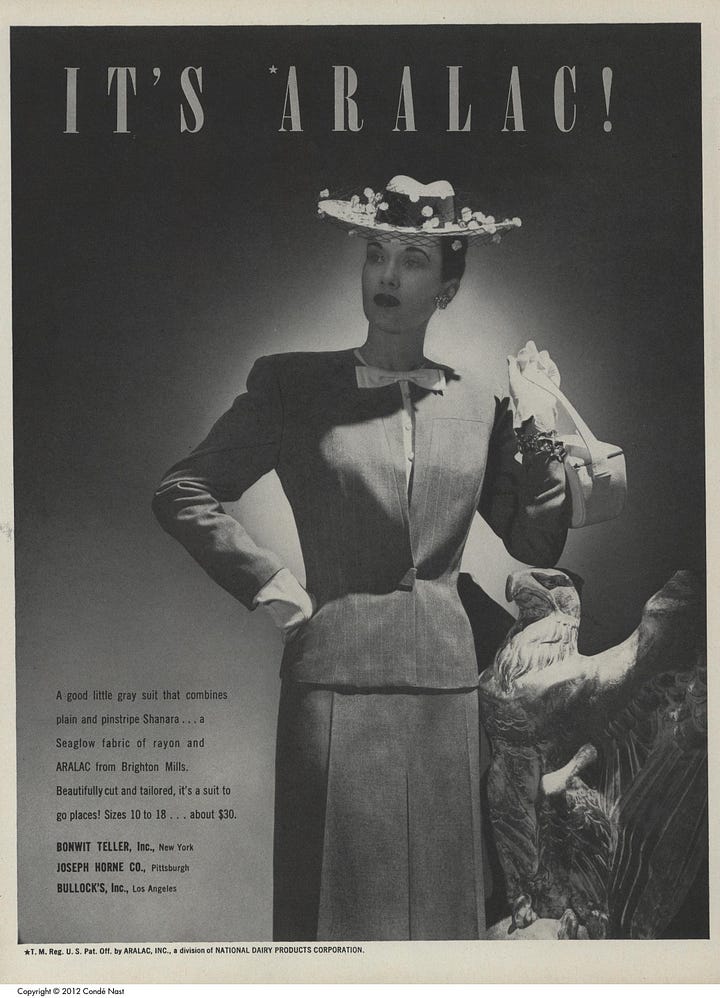

Aralac was primarily designed to be blended with other fibers like rayon. Vintage advertisements from Vogue and Women’s Wear Daily show the fiber was often used for suiting, nightwear, and as an interlining in coats. Aralac shared many properties with wool, such as its moisture-wicking and insulation abilities. When wool became reserved for the military during World War II, Aralac was advertised as the perfect alternative. Purchasing clothing made with Aralac was seen as a contribution to the war effort.

However, once the war ended and wool became easily accessible to civilians again, Aralac struggled to retain a share of the fiber market. Aralac had some weaknesses, such as low durability and high production costs. It took about 100 pounds of milk to produce just 3 pounds of milk fiber. Eventually, fully synthetic fibers like acrylic replaced Aralac as a cheaper alternative to wool.

Just like this 1940s hat, every object in the Parodi Costume Collection hides a captivating story just waiting to be discovered

Merrimac Hat Corp, Felt Hat, 1940s, from the Headwear/Accessories archive at Parodi Costume Collection.

Text by: Sophie Bessell

Work Cited

“Advertisement: Aralac (Aralac).” Vogue 105, no. 9, May 1, 1945.

“Advertisement: Aralac (Aralac, Inc.).” Women’s Wear Daily 66, no. 22, February 2, 1943.

“Fashion: Milk-Made Coat.” Vogue 100, no. 3, August 1, 1942.

“Making Wool From Milk (1937).” YouTube, April 14, 2014.

www.youtube.com/watch?v=OyLnKz7uNMQ

“Rayon and Aralac Fabric Sample, Carter Fabrics Corporation.” National Museum of American History, May 13, 2025. https://americanhistory.si.edu/collections.

Rodger, Katie. “Back to the Future? Milk Fiber in the 21st Century.” International Milk Genomics Consortium, 2019. https://www.milkgenomics.org/?splash=back-to-the-future-milk-fibers-in-the-21st-century.

Waters, Michael. “How Clothing Made from Milk Became the Height of Fashion in Mussolini’s Italy - Atlas Obscura.” Atlas Obscura, July 28, 2017. https://www.atlasobscura.com/articles/lanital-milk-dress-qmilch.